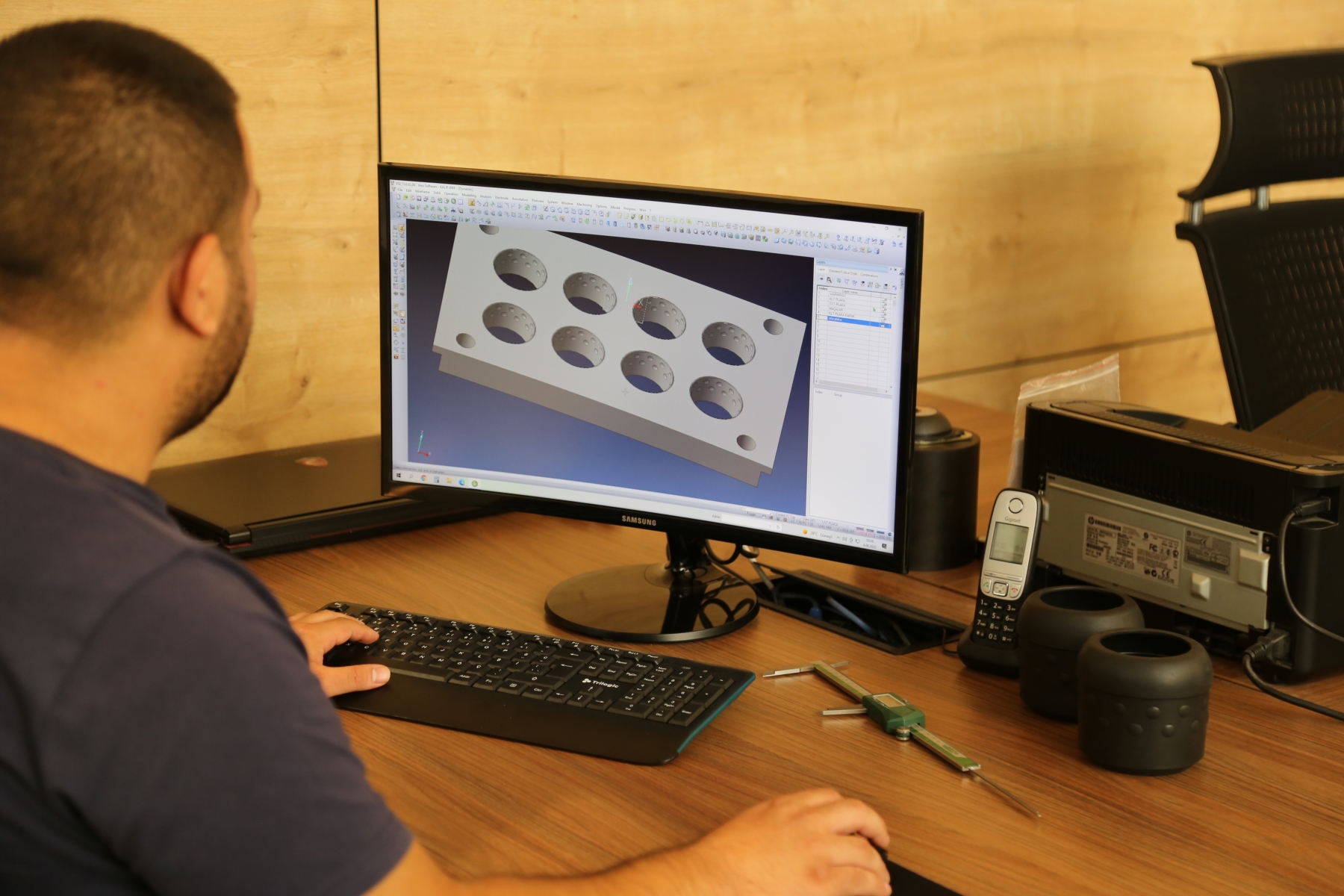

Mould Design & Manufacturing

We design and produce our tooling by. NC and CNC machines

CNC Machining

We process the machining of metal

and plastic parts with CNC lathes.

and plastic parts with CNC lathes.

Metal Forming and Welding

Metal forming and welding is process using advanced production methods in our production.

Grid Blasting

We sandblast metal parts before ad-

hesive application to get fully clean,

activate and pretreat the surface.

hesive application to get fully clean,

activate and pretreat the surface.

Adhesive Application

The application of bonding agent

is process with our fully automatic

machines.

is process with our fully automatic

machines.

Precision preformer

We prepare mixtures according to customer request. Mixtures are pre-form before vulcanization to reduce waste cosy according to tooling design and shape.

Injection Molding

Our advanced technology rubber injection presses provide fully automatic loading and unloading, as well as enabling us to produce high quality.

Compression Molding

Preformed rubber compounds and metal parts are converted into the

final product in hydraulic presses by compression molding process.

Rubber & Metal Laboratory

Mixtures are controlled by laboratory equipments to maintain standart quality. We control the stiffness and rubber to metal bonding levels among other parameters using the latest control methods.

Packing & Delivery

Parts are packaged according to customer requirements, ensuring safe and undamaged shipping.